262642

0

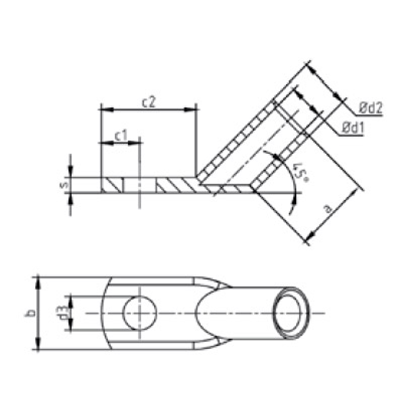

45° angular copper ring eyelet, tin-plated 25mm² for M10 screw 5 pcs. SE45-02510

Product description

SE45 series copper tubular lugs (tin-plated) for crimping. They enable the termination of copper cable cores, they are used where it is necessary to connect the incoming cable at an angle of 45° to e.g. switchgear, busbar or other device by means of a screw terminal. The use of SE45 ring terminals increases the safety and durability of this type of connection. In contrast to soldered connections, the use of ring terminals reduces the risk of overheating of wires and insulation. In case of pressing sector cores, they should be reformed into “round”.

All copper pipe lugs distributed by TRYTYT are subjected to an additional process of hardening and firing at 700°C. This process removes any impurities from the tip material. Hardened terminals, as opposed to non-hardened terminals, are less likely to develop cracks and micro-cracks during crimping, and thus have better working parameters.

The effectiveness of crimping (fixing the terminal on the cable) depends on the use of an appropriate tool and a die adapted to the cross-section.

Technical data

-

MaterialElectrolytic copper

-

Inner diameter [mm]7

-

ScrewM10

-

PKWIU27.33.13.0

-

Pieces in the package5

-

Outer diameter [mm]10

-

cross section [mm²]25

Manufacturer details

-

ManufacturerTRYTYT Sp. z o.o.

-

Address43-382 Bielsko-Biała Horeszków 8 Polska

-

E-mail