Dobór wyłącznika silnikowego

Wyłącznik silnikowy

Moc silnika

Najczęściej wyłączniki silnikowe stosowane są do zabezpieczenia silników o małej mocy – do około 4kW. W wyjątkowych sytuacjach stosuje się także wyłączniki umożliwiające łączenie silników większych mocy.

Funkcje wyłącznika silnikowego

Nieodpowiednio pracujący silnik narażony jest na zniszczenie i może być przyczyną pożaru – koniecznym jest więc zabezpieczenie go (i całej instalacji) przed skutkami:

- zwarć (za błyskawiczne rozłączenie odpowiedzialny jest wyzwalacz elektromagnetyczny – czas zadziałania jest rzędu milisekund)

- zaniku faz zasilania (asymetrii fazowej)

- przeciążeń i zablokowanego rozruchu (odpowiedzialny za to jest wyzwalacz termiczny)

Dobór nastaw wyłącznika silnikowego

Wyłączniki silnikowe wyposażone są w pokrętło służące do ustawienia prądu rozłączenia – ustawia się go według prostego wzoru:

Inas = In * 1,1, gdzie

In - prąd znamionowy silnika

Inas - prąd nastawy wyłącznika

Na przykład do zabezpieczenia silnika o prądzie znamionowym 10A pokrętło powinno się nastawić na 11A (10*1,1).

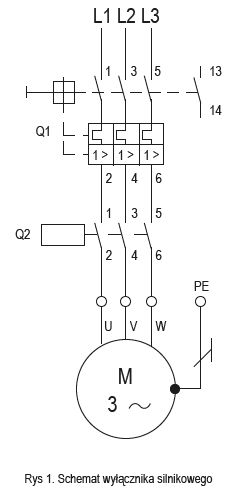

Montaż wyłącznika silnikowego

Kluczową kwestią jest montaż wyłącznika zawsze przed stycznikiem – uchroni to stycznik przed skutkami ewentualnych zwarć.

|

Pozostałe informacje

Istotną kwestią przy wyborze wyłącznika silnikowego jest także prąd zwarciowy. Parametr ten świadczy o maksymalnym prądzie, który może przepłynąć w trakcie zwarcia, nie uszkadzając trwale wyłącznika.

W instalacjach wykorzystujących wiele silników pracujących równolegle należy pamiętać, aby każdy z silników zabezpieczony był oddzielnym wyłącznikiem – zapobiegnie to awarii w razie, gdy jeden z silników będzie obciążony w większym stopniu od pozostałych.